How it works

SiteAware Digital Construction Verification streamlines the construction process through automated quality control, ensuring that you build as planned

The tech that powers SiteAware Build•To•Plan™

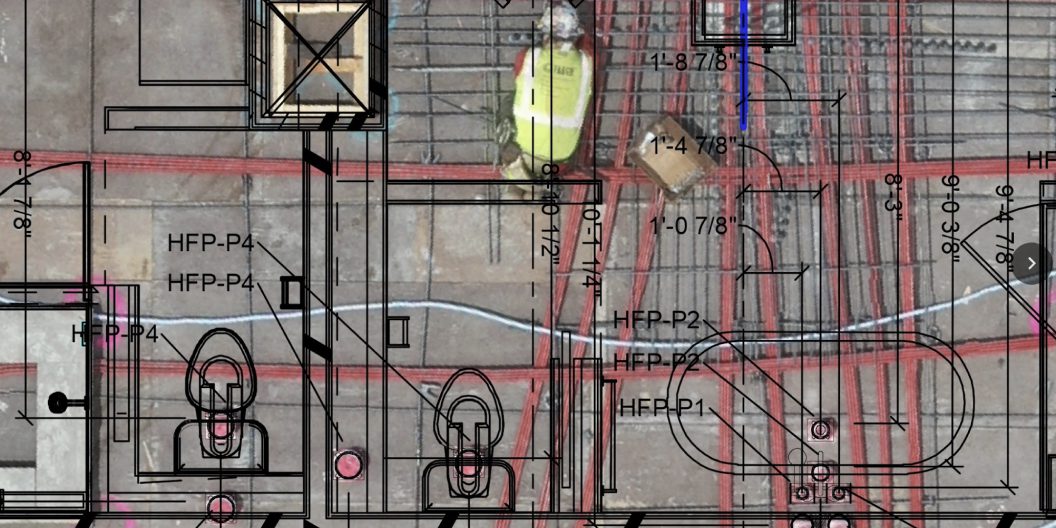

Plan tagging

Differences in CAD and BIM standards make it hard to turn plans into data, so we created a common language for every element that is installed. That enables Build-to-Plan™ to connect to your plans, regardless of the software or documentation you use, and connect every project through a single database. Turning every sleeve, gasket, and embed into a data point that reflects its quality, schedule, and location creates a universal vocabulary, breaking down silos of information between project participants. With various technologies integrated into the platform, Build-to-Plan™ is suited to every use case.

Automated scanning

3D scanning captures detailed data on all structural elements and MEPF, facade layers, and interior installations. For technology to effectively integrate into existing workflows, it needs to be a net gain; that’s why we created scanning processes that work automatically and in the background as you build. This enables a faster and more productive construction process, from start to finish.

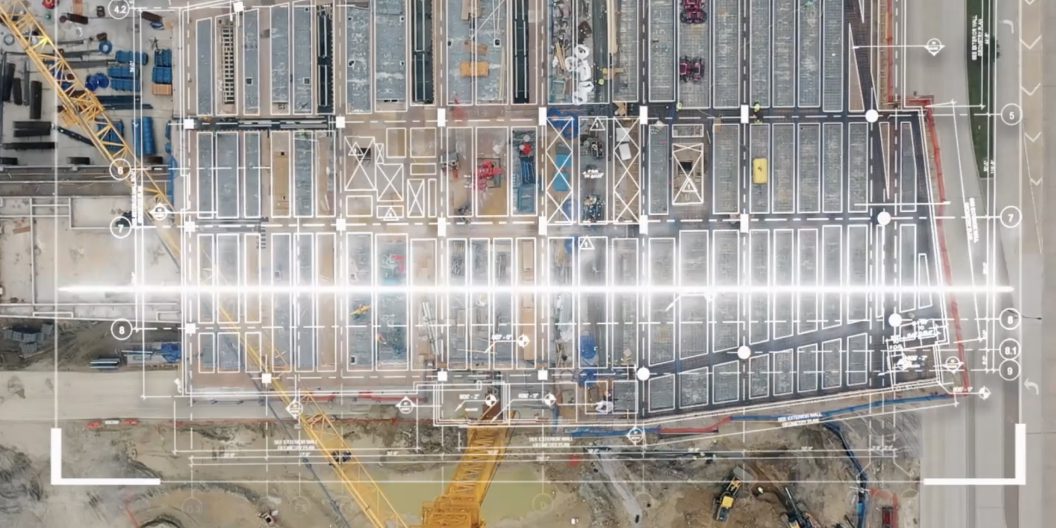

Fast, accurate digital twinning

Documentation of construction should be virtually automatic, just as it is in any modern manufacturing process. Our automatically generated multi-layered as-builts serve as a virtual X-ray of the structure, shell, and interiors. With a solution specifically for buildings, Build-to-Plan delivers an exact digital replica of the jobsite, documenting the quantity and dimensional location of every element to elevate certainty in project execution and management. For this to support your workflows, we’ve created a standard that meets construction tolerances — and does it in record time.

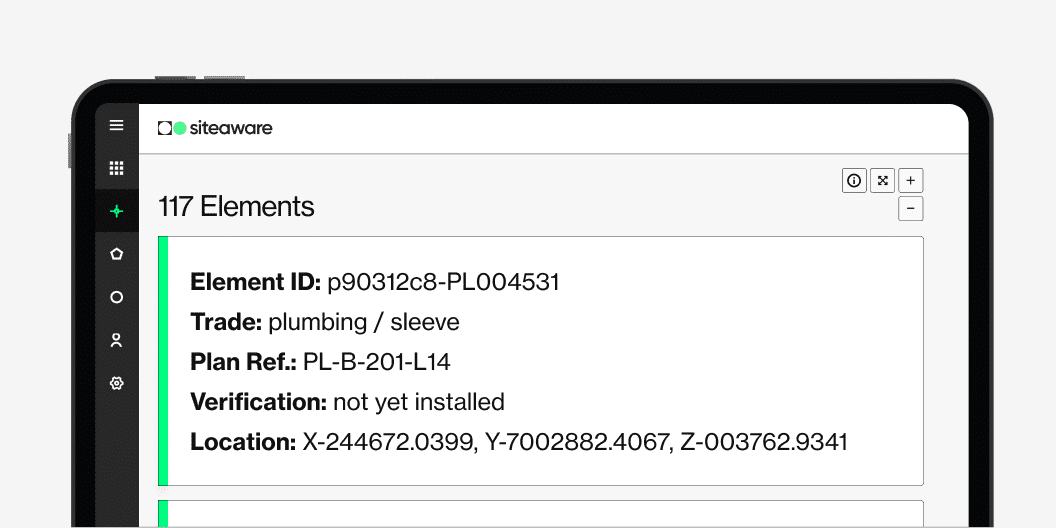

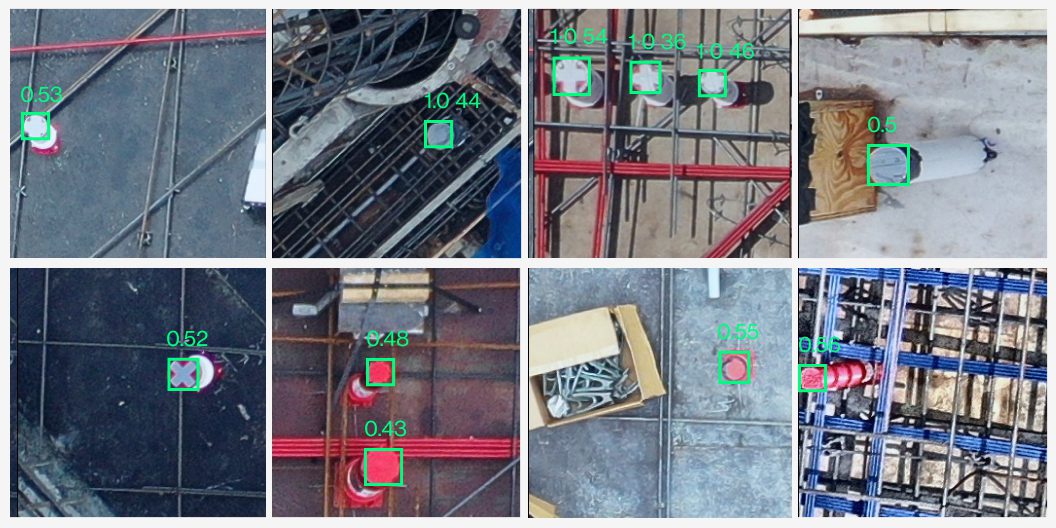

AI verification

Build-to-Plan™ utilizes artificial intelligence (AI) to verify that each element is built according to its plan. This enables Build-to-Plan to provide fast real-time data, feedback, and actionable insights to reveal patterns that help teams uncover errors, prioritize fixes, and make better decisions about everything from the subcontractors they choose to how they enable better coordination between trades.

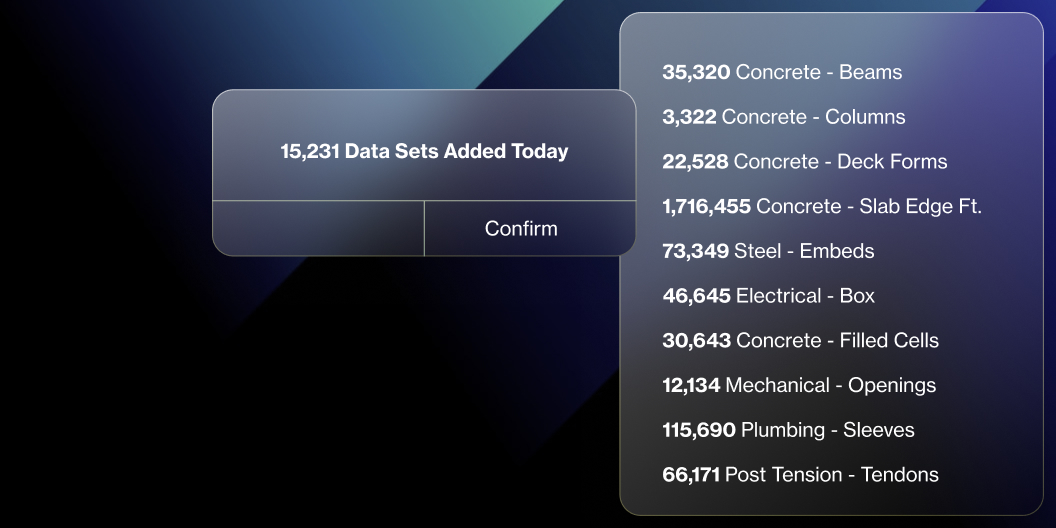

Rich data

A rich, comprehensive data set derived from millions of construction elements across hundreds of projects informs industry-wide metrics and uncovers insights into trade performance that affect projects today, serve as leading indicators for overall project performance, and determine the exposure and direction of your business.